Past Projects

Jet Propulsion Laboratory - Europa Clipper

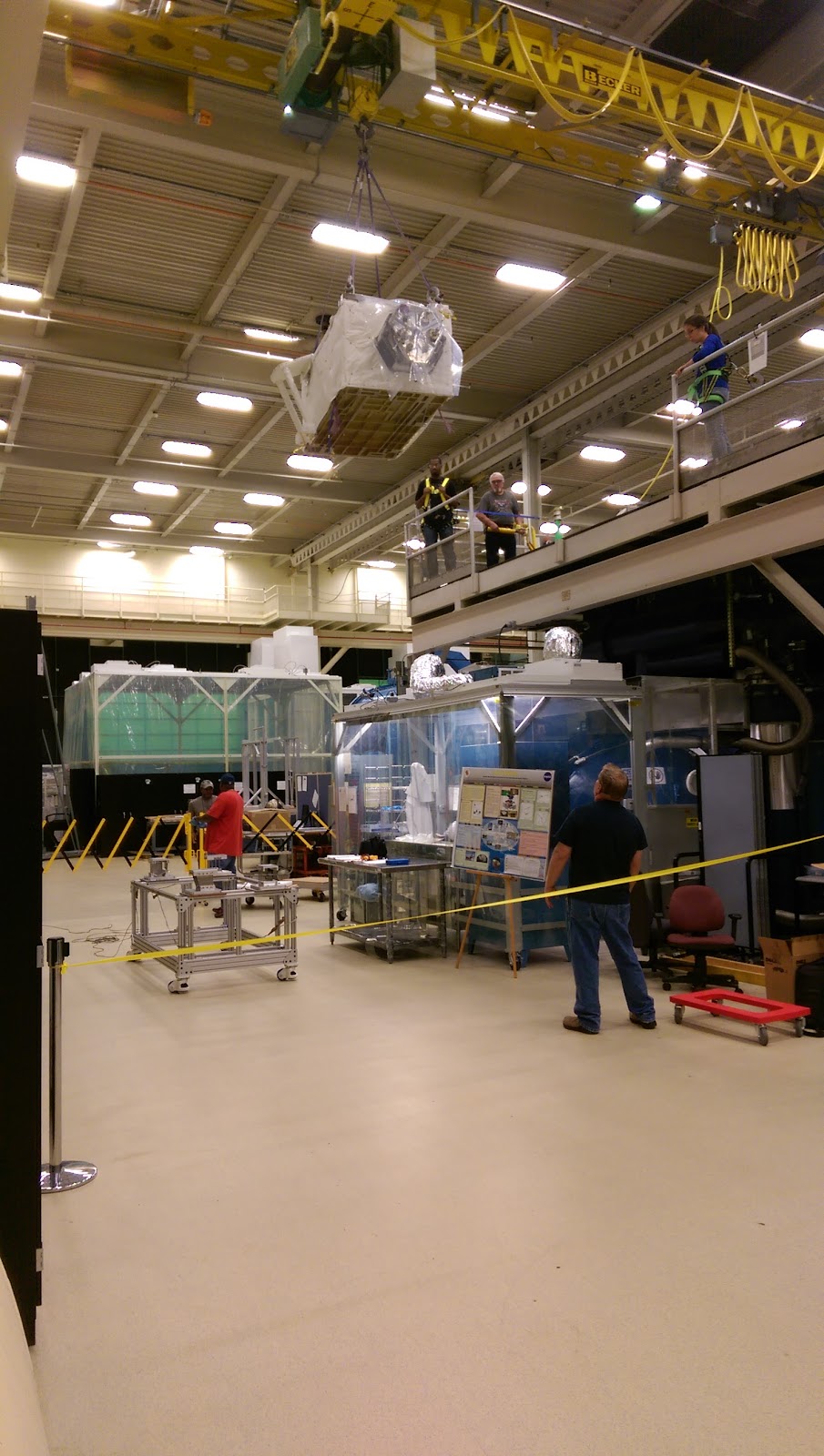

Thermal Vacuum Chamber Lift Fixture

This lift fixture was used as the interface between the spacecraft and the historic 25-foot diameter space simulator at the Jet Propulsion Laboratory.

Designed and analyzed to support 8000 lbs of working load to JPL's DocID 35412, through a temperature range of -180°C to +90°C.

Installation completed in November 2023, with last minute re-design and installation completed in January 2024. Spacecraft installed in February 2024,

and completed testing in March 2024.

Hardware required fast turn re-design in order to accommodate support MGSE delay and not being able to pass a proof test. The TVAC lift fixture was updated

in less than 3 weeks, including getting hardware fabricated and proof tested.

COTS Scaffolding

Provided three Commercial Off The Shelf (COTS) scaffolds to the project to support various integration work flows, including concurrent integration activities. Scaffolds include the High Gain Antenna (HGA) scaffold (shown to the left), TVAC installation scaffold, and the Vault Walk Around scaffold. The HGA scaffold was used by the project to maintain schedule and support additional integration activities while the primary assembly scaffold was delayed. The Vault Walk Around scaffold was used to provide multiple personnel access to the avionics section of the spacecraft. Both of these scaffolds can be reconfigured into multiple positions to provide easier access to various hardware. The TVAC installation scaffold was a quick turn project to support the necessary redesign due to other TVAC MGSE not being available.

COPV Tank Protective Covers

4 remove before flight sheet metal covers were provided to prevent any accidental contact to the COPV tanks. Additional smaller support tools were also provided into in order to ensure simple installation of the covers, and to prevent any accidental contact being made to the tanks.

Previous images belong to JPL and NASA.

Goddard Space Flight Facility - ISS Cream

CREAM Lift Fixture

Designed and analyzed the payload lift fixture to NASA-STD-8719.9. Total capacity was 2700 lbs.

CREAM Test Stands and Dollies

Re-purposed two dollies/stands that were in storage for use on CREAM. One was the assembly and transportation dolly (pictured left). The other was the EMI and TVAC cart, used for EMI/EMC testing and preparation for TVAC testing. Both were updated per GSFC 540-PG-8700.2.2 and NASA-STD-5005.

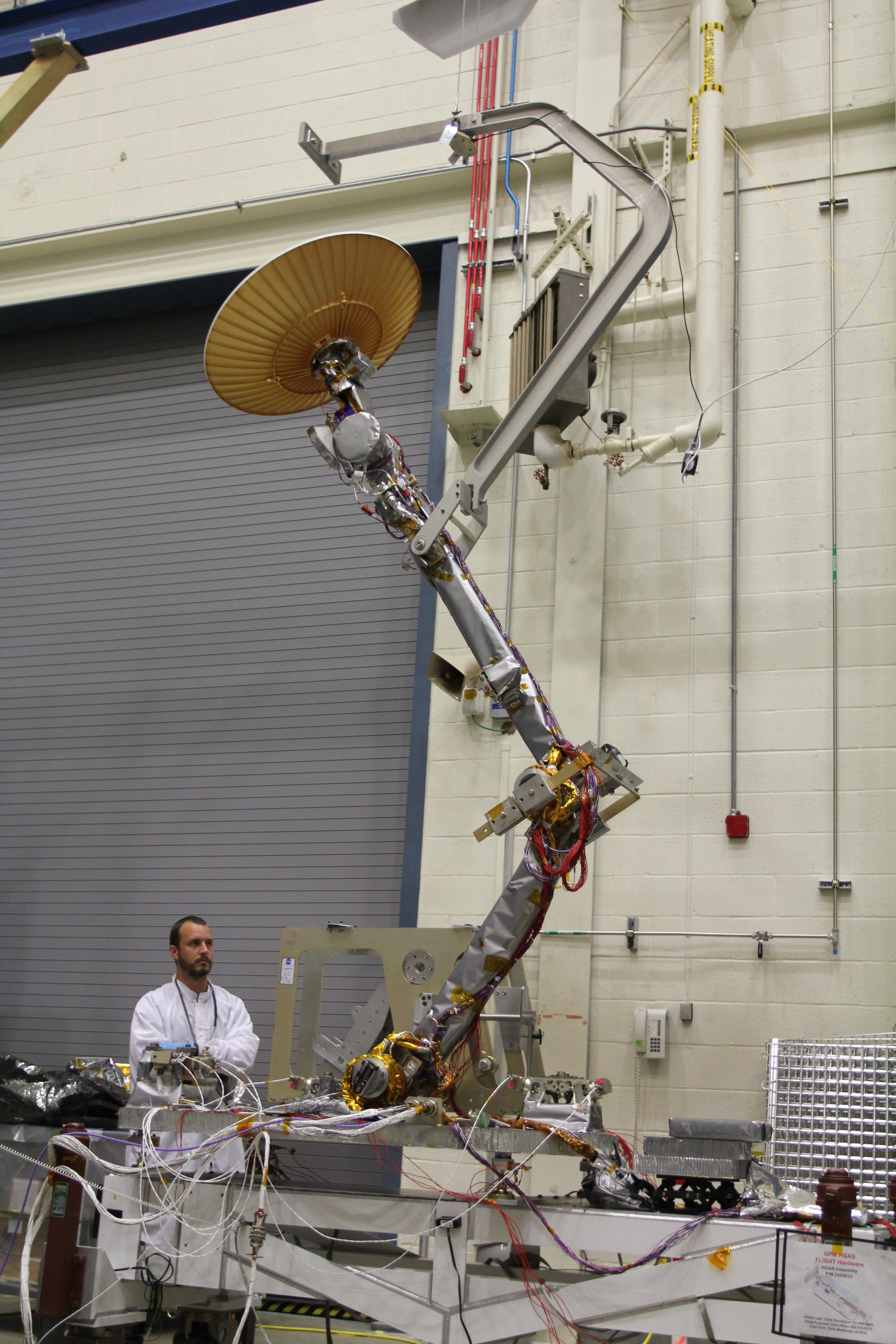

Goddard Space Flight Center - GPM Core Observatory HGAS

High Gain Antenna (HGA) System's Hinges

Designed, analyzed, and qualified two hinges and their respective booms to deploy the High Gain Antenna for the core observatory. Primary integration engineer for the subsystem, integrating the antenna, gimbals, and launch restraint mechanisms to the deck. Coordinated efforts between Thermal, MLI technicians, and MGSE support. Also was the Integration & Testing liaison for the the subsystem, coordinating g-negation activities, subsystem closeouts, and integration to the spacecraft.

W. L. Gore & Associates

Transcatheter Aortic Valve Replacement (TAVR)

Designed and analyzed self-expanding and balloon expandable TAVR devices through conceptual development. Additionally supported the manufacturing line with providing tooling, laser patterns, and test fixtures.

Reliability Engineering

Standardized the cardiac reliability lab to improve testing results and test through put. Standardization has since been adopted by the test equipment provider (shown left). Provided support to qualify new product lines for acceptance by the FDA, and additional test support for new product development. Developed applicable tests to mimic in-vivo boundary conditions. Also developed custom excel and python scripts to analyze data, and generate boundary conditions from in-vivo measurements.

Previous image belongs to TA Instruments.